TRUSS DESIGN PROJECT

Constraints

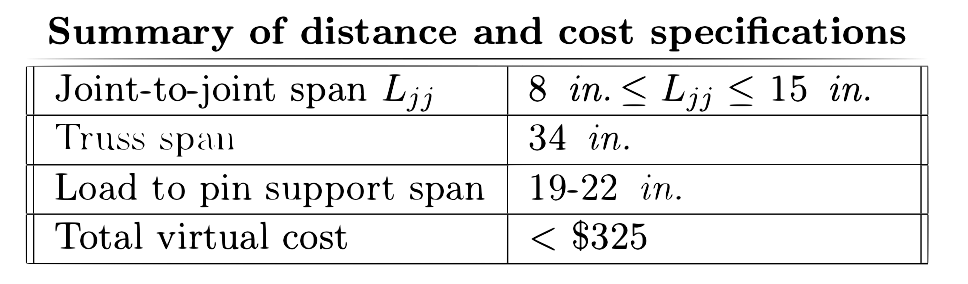

The truss to design had to conform to some specifications such as:

being be a single, planar, simple truss,

no truss member may be designed to extend below the line connecting the two end joints

the truss must be designed to support a minimum live load of 32 oz.= 2lb (located at a horizontal distance of 19-22 in. away from the pin support)

The total (virtual) cost of the truss must be less than $325 where the cost of the truss is defined as

Cost = C1J+C2L

where: C1 = $10/joint

C2 = $1/in.

with J = number of joints and L = total length of all members summed together.

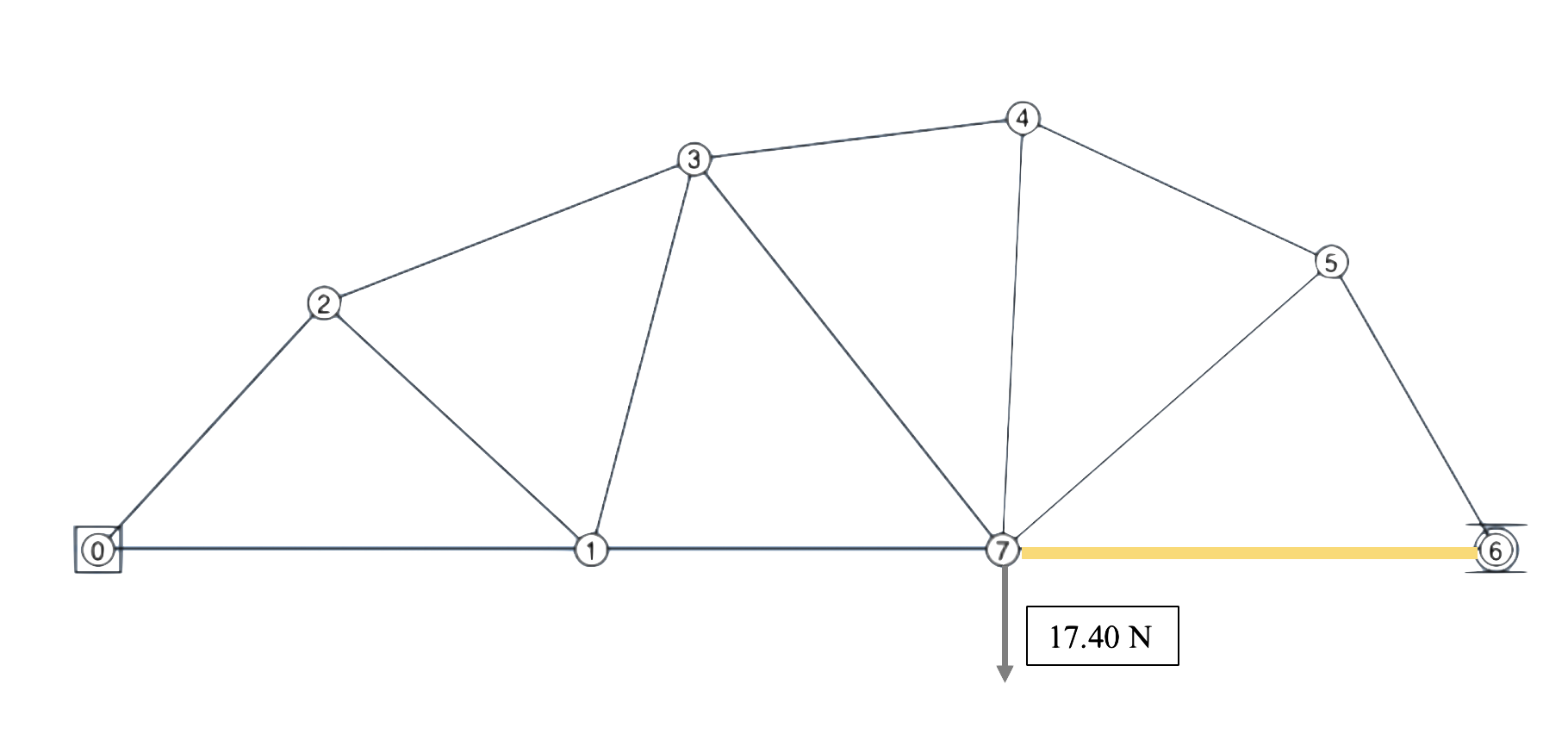

After having experimentally derived the equation for the critical buckling load of acrylic member as a function of length, we developed a MATLAB script that, after having received as input the coordinates for the nodes and members, it can predict the maximum load and the first member that fails.

Results

As result the truss held 1700g while the predicted mass was 1774g, indicating a success of the design and analysis prediction. We also optimized the load-to-cost ratio and after several designs we ended up obtaining a great result, within the top 10% of the class.

Virtual 2D Model

Real Model